We use cookies for this website, which we divide into essential and analytical according to their purpose. Essential cookies help us make our website as usable as we need it to be. Without them, our website would not function properly and we do not need your consent to use them. Analytical cookies help us understand how you use our site. They collect and communicate information anonymously to the tools we use. Clicking the “Accept all” button means we can use all cookies. You can read more about cookies HERE.

ALL THE ESSENTIALS YOU SHOULD

KNOW ABOUT US.

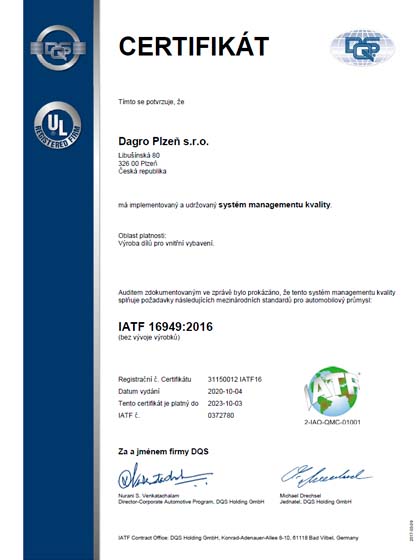

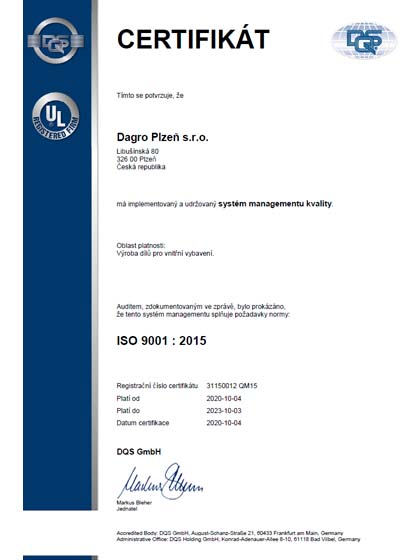

CERTIFICATES

YOUR WARRANTY OF TOP QUALITY.

We are a long-term holder of two quality certificates:

IATF 16949:2016

ISO 9001:2015

FOR QUALITY CONTROLLERS

HOW DOES DAGRO GUARD THE QUALITY OF EVERY PRODUCT?

We deliver only top quality to all our clients - regardless of their type, size or focus. Meeting our clients' requirements means defining processes from first contact to delivery and service - and, of course, following and continually improving them. To do this, we use a detailed overview of all processes in our company. And because it is linked to the specific applicable procedures (quality management manual, guidelines...), it serves as an indicator of our quality management system. As a matter of course, we are constantly adapting the system and all relevant documentation to changes in the organization and to the development of the company. The management system at DAGRO is based on the requirements of the applicable wording of ISO 9001:2015 and IATF 16949:2016 standards.

Our guidelines describe the following processes in detail:

Our guidelines describe the following processes in detail:

- Sequences of activities and interactions between processes (especially the inputs and outputs at interfaces)

- Criteria and methods for effective process control

- Resources (assets and personnel) and information needed to implement and control the processes

- Measurement, control and analysis of processes to review the planned results and improvements

- We ask for any specific customer requirements prior to the start of the project as part of the project management process. They are then updated once a year through customer portals or by asking the customer

DAGRO ENVIRONMENTAL POLICY

WE MANUFACTURE WITH THE LOWEST POSSIBLE ECOLOGICAL FOOTPRINT.

We in Dagro are well aware of the fact that our manufacturing activities affect the environment. And if its condition is on your company\'s mind as well, we\'re on the same page.

Thanks to our environmental policy, you can be sure that we will deliver your order with the lowest possible environmental impact:

Thanks to our environmental policy, you can be sure that we will deliver your order with the lowest possible environmental impact:

- We put emphasis on prevention in reducing the environmental impact of our manufacturing processes and procedures

- We evaluate our impact on the environment regularly and take specific measures immediately as required

- Both in new and current job orders we always consider their potential impacts on the environment and always prefer the procedures and materials with the lowest possible form of ecological footprint

- We comply with the legislation, regulations and decrees issued by the local public administration authorities in relation to environmental protection

DAGRO HOLDING STRUCTURE

GET ACQUAINTED WITH OUR 5 MANUFACTURING DIVISIONS.

DAGRO AUTOMOTIVE

Serial production of upholstery parts for the global leading automotive concerns (BMW, Mercedes-Benz, Audi, etc.). We specialize in complicated interior parts which cannot be upholstered mechanically but manually only.

CUT & SEW DIVISION

The division specializes in cutting, skiving, splitting and sewing. As long-time professionals, our employees work with all kinds of quality materials: Alcantara, imitation and genuine leather and all types of fabrics.

ECO DIVISION

Alternative processing methods and the use of a wide range of conventional and eco-friendly materials: This is the way we contribute to sustainable development.

DAGRO EXCELLENCE

This division focuses on the custom handmade production of unique upholstery parts for clients in the healthcare, furniture, sports and fitness, aviation or transport (trains, etc.) industries.

NAFIGO

Production of high-end nanofiber masks for B2B and B2C. Using the NanoSpider technology, we have developed a proprietary type of nanofiber and a smart design for the nanofiber masks that can be used safely for up to 90 days. We have developed our own type of nanofiber. We supply NAFIGO nanofiber masks all over the world, in any design customized to client's wishes.For more details visit www.nafigo.cz

DAGRO IN NUMBERS

WHAT WAS THE YEAR 2021 LIKE FOR US AND WHAT ARE OUR VISIONS?

1959

THE YEAR OF COMPANY ESTABLISHMENT

THE YEAR OF COMPANY ESTABLISHMENT

205 CZK

YEARLY TURNOVER IN MILLION IN 2021

YEARLY TURNOVER IN MILLION IN 2021

185

OUR WORKFORCE IN 2021

OUR WORKFORCE IN 2021

430614

THE NUMBER OF PARTS MANUFACTURED IN 2021

THE NUMBER OF PARTS MANUFACTURED IN 2021

OUR MISSION IS TO PRODUCE PREMIUM QUALITY UPHOLSTERY PRODUCTS FOR THE AUTOMOTIVE, FURNITURE, SPORTS AND OTHER INDUSTRIES.

WE ALWAYS STRIVE TO FIND THE BEST SOLUTION FOR OUR CUSTOMERS.

WE PRIDE OURSELVES ON CREATING AND MAINTAINING LONG-TERM BUSINESS RELATIONSHIPS TO MUTUAL SATISFACTION.

WE ALWAYS STRIVE TO FIND THE BEST SOLUTION FOR OUR CUSTOMERS.

WE PRIDE OURSELVES ON CREATING AND MAINTAINING LONG-TERM BUSINESS RELATIONSHIPS TO MUTUAL SATISFACTION.

OUR PEOPLE ARE THE CORNERSTONE OF A WELL-FUNCTIONING AND PROSPEROUS COMPANY, AND THAT IS WHY WE STRIVE TO MAKE OUR EMPLOYEES FEEL SATISFIED IN THE LONG TERM.

WE PROVIDE THEM WITH THE PROSPECT OF PROFESSIONAL AND PERSONAL DEVELOPMENT. AND IT IS ON THESE IDEAS THAT OUR COMPANY WANTS TO BUILD IN THE FUTURE.

WE PROVIDE THEM WITH THE PROSPECT OF PROFESSIONAL AND PERSONAL DEVELOPMENT. AND IT IS ON THESE IDEAS THAT OUR COMPANY WANTS TO BUILD IN THE FUTURE.