OUR SCOPE OF BUSINESS

AUTOMOTIVE INDUSTRY

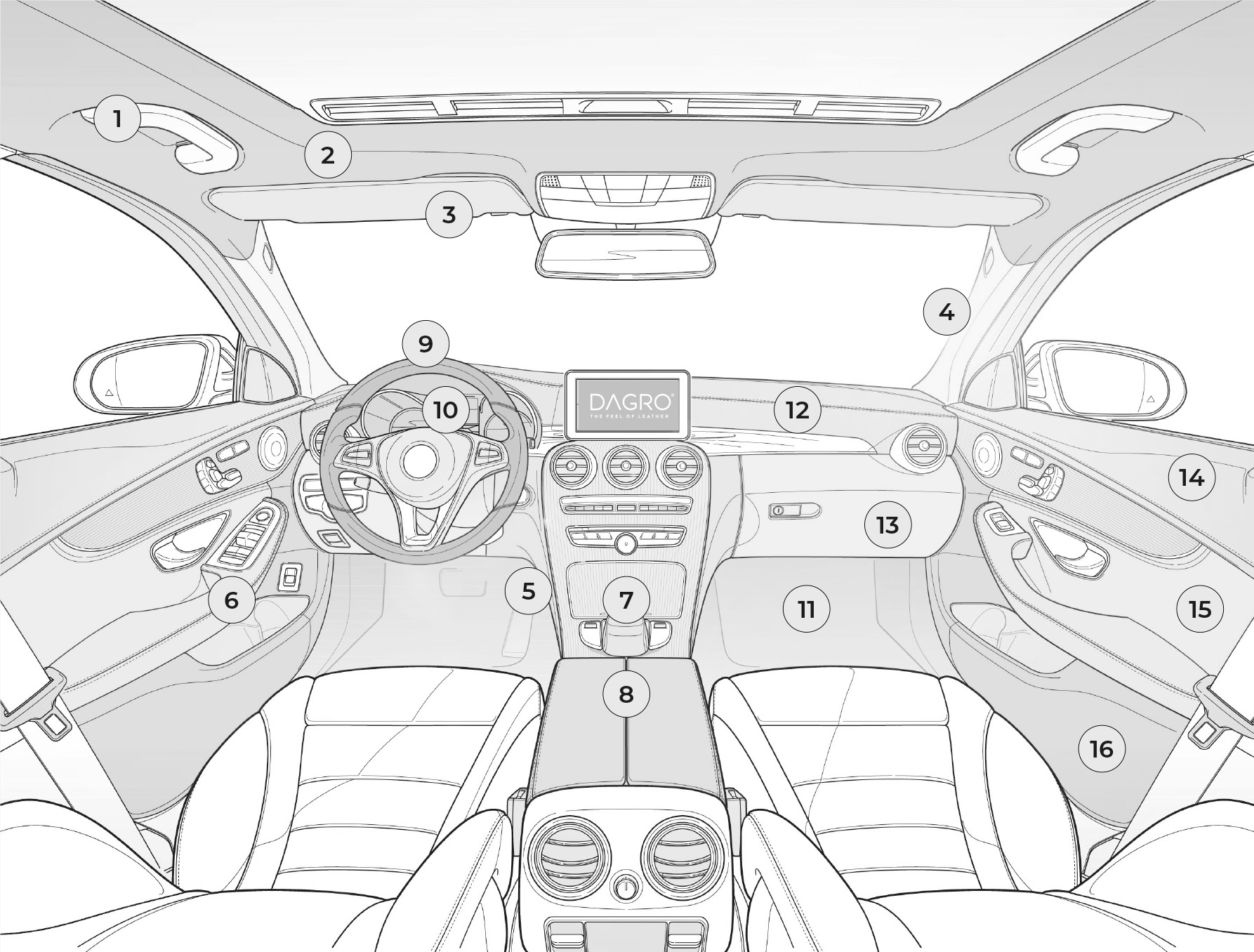

This segment is our flagship. For decades Dagro has been supplying hand-upholstered parts to the world's leading car manufacturers from Audi to BMW, Mercedes-Benz to Lamborghini. We focus on complex interior parts and fine materials that can only be upholstered by hand.AUTOMOTIVE INDUSTRY

CUSTOM MANUFACTURING

We also offer custom manufacturing to clients outside of the automotive industry, including smaller or diverse orders or projects. Whatever your project, you can always count on a flexible response to your needs and an established quality control system that is common in the automotive segment.CUSTOM MANUFACTURING

AIRCRAFT AND TRANSPORT INDUSTRIES

We supply hand-upholstered parts for cargo aircraft (such as British Airways), passenger trains, buses and other means of public transport. Here too you will find many parts that cannot be sewn or upholstered mechanically - an ideal opportunity for the skilled hands from DAGRO.AIRCRAFT AND TRANSPORT INDUSTRIES

HEALTHCARE

We understand that during medical procedures and physiotherapy, patient\’s comfort is crucial both for recovery and for the reputation of the medical facility. That's why we have successfully extended our experience in upholstering and sewing for the automotive industry to include premium upholstery products for the healthcare industry.HEALTHCARE

SPORTS

In sports, we specialize in the custom production of upholstery for fitness, massage and physiotherapy machines of all types, but also for racing cars.SPORTS

FURNITURE

We supply both serial and custom production for the furniture industry. Our offer covers furniture upholstery and individual design elements to furnishing luxury hotels or offices.FURNITURE

SERVICES AND TECHNOLOGIES

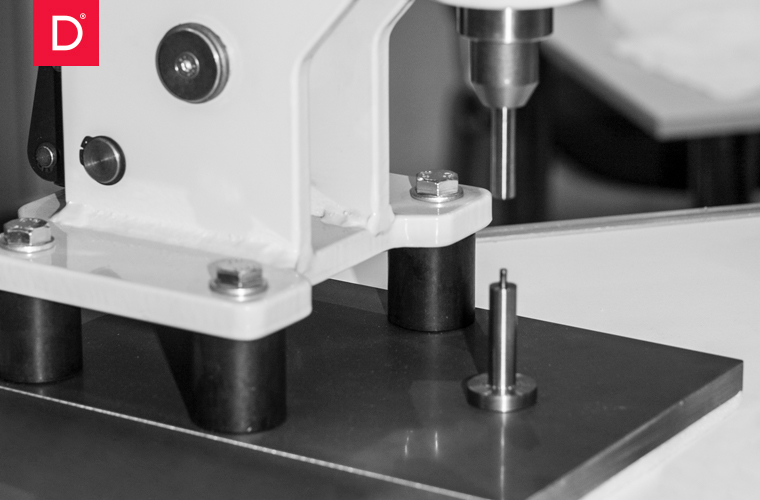

DIE-CUTTING

We use a first-class die-cutting press from the German manufacturer Schön & Sandt AG. Thanks to the machine, we can cut practically any shape you require for your project from whole leather pieces. To ensure that every piece produced is of top quality without exception, our trained staff will mark out any defects (scars, wrinkles or even insect bites) on the leather before cutting. Only then they cut out blanks, which are then worked manually. Machines can be used to cut out any material from leather, imitation leather or any ordinary fabric.

SPLITTING

Leather thickness is adjusted during splitting. The reason for this process is the different requirements for upholstering various interior parts. For larger parts (seats or ceiling panels), greater thickness is more suitable, while for small parts, thinly split (even under 1 mm) leather is preferable. Thinner leather is easier to work with when upholstering, as it is easier to bend and shape. On the other hand, due to the minimum thickness, there is always a risk of breakage, which requires our upholsterers to work with utmost care.

SPLITTING

Leather thickness is adjusted during splitting. The reason for this process is the different requirements for upholstering various interior parts. For larger parts (seats or ceiling panels), greater thickness is more suitable, while for small parts, thinly split (even under 1 mm) leather is preferable. Thinner leather is easier to work with when upholstering, as it is easier to bend and shape. On the other hand, due to the minimum thickness, there is always a risk of breakage, which requires our upholsterers to work with utmost care.

SKIVING

Skiving is another of the not-so-common processes that only a truly quality company will offer. With us in DAGRO, it is a standard activity. Skiving is used to reduce the thickness of the leather around the edges of the individual cuts where the cuts are stitched together. The reason for skiving is to reduce the thickness of the leather in the place of stitching so as to maintain a uniform thickness of the leather at the seam and beyond. At DAGRO, we operate two skiving machines at your disposal.

UPHOLSTERING

Manual upholstery is our premium service. The upholstery process always begins with the spraying of adhesive on the upholstery material and on the substrate onto which the material is then placed. To protect the environment, we are still increasingly using water-based adhesives. We coat the parts with PUR foam alongside the top material to soften the final effect. The coating is done by hand by our upholsterers. The stitched parts (cut-outs) are shaped by hand, the edges are set and then trimmed.

UPHOLSTERING

Manual upholstery is our premium service. The upholstery process always begins with the spraying of adhesive on the upholstery material and on the substrate onto which the material is then placed. To protect the environment, we are still increasingly using water-based adhesives. We coat the parts with PUR foam alongside the top material to soften the final effect. The coating is done by hand by our upholsterers. The stitched parts (cut-outs) are shaped by hand, the edges are set and then trimmed.

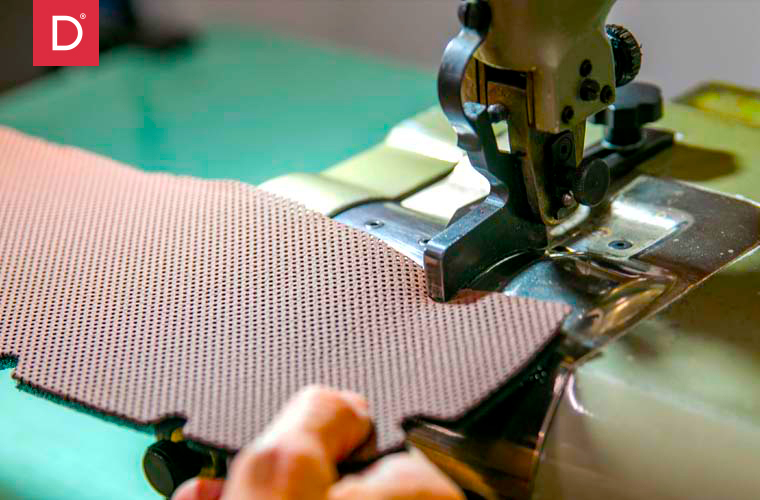

SEWING

Sewing is done by professional seamstresses having many years of experience in the field. A well-sewn piece is the basis of all upholstery work, so we pay maximum attention to the quality of the sewing process, as well as to the ongoing training of our seamstresses. Our sewing workshops are equipped with top industrial sewing machines from PFAFF and Adler. We have single and double needle machines, arm sewing machines, overlocks and other special machines including fully automatic ones.

VACUUM LAMINATION

Vacuum lamination of some specific parts is one of the fully automated processes at DAGRO Automotive in those projects which require mechanical backing explicitly and where the process automation contributes to a high production capacity. We use presses with the technology of thermal heating of parts with vacuum fixation. Among the parts that DAGRO Plzeň produces in this way are, for example, door panels.

VACUUM LAMINATION

Vacuum lamination of some specific parts is one of the fully automated processes at DAGRO Automotive in those projects which require mechanical backing explicitly and where the process automation contributes to a high production capacity. We use presses with the technology of thermal heating of parts with vacuum fixation. Among the parts that DAGRO Plzeň produces in this way are, for example, door panels.

LAMINATION

This concerns the joining of layered materials, usually as face layers (fabric, leather, imitation leather, alcantara, dynamica) with a softened bottom layer. In order to achieve the best possible performance properties of the product, especially its softening, we use the thermoforming technology.

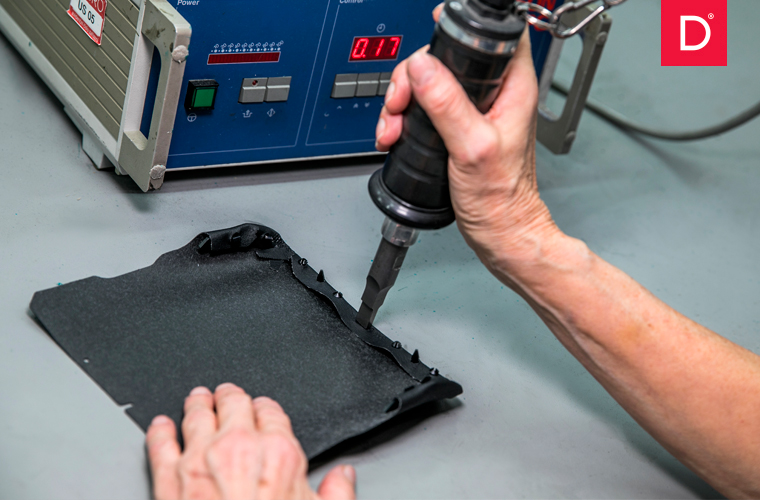

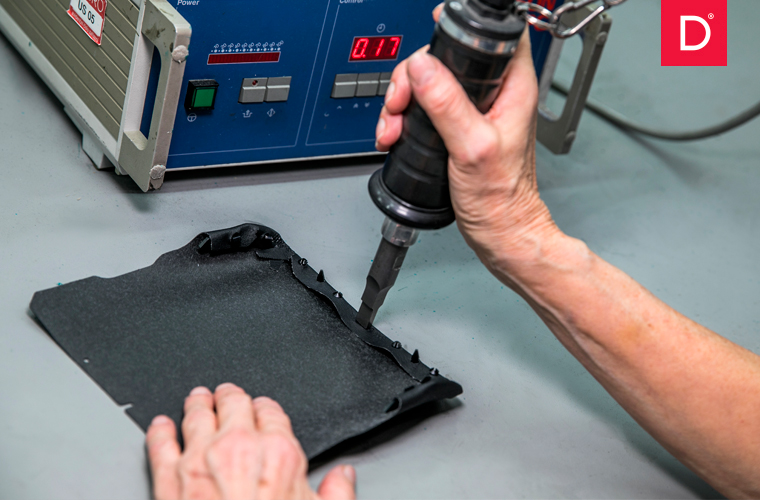

ULTRASONIC WELDING

This method of welding of thermoplastics and other materials using the oscillating ultrasonic energy at the joint (weld) is used in the manufacture of some specific interior components. The joint is formed by perpendicularly applying ultrasonic oscillations to the plane of the joint while applying a clamping force simultaneously. The action of heat causes softening at first and then fusion. The result is a solid bond at the resulting joint.

ULTRASONIC WELDING

This method of welding of thermoplastics and other materials using the oscillating ultrasonic energy at the joint (weld) is used in the manufacture of some specific interior components. The joint is formed by perpendicularly applying ultrasonic oscillations to the plane of the joint while applying a clamping force simultaneously. The action of heat causes softening at first and then fusion. The result is a solid bond at the resulting joint.

ADHESIVE SPRAYING

The upholstery process always begins with the application of an adhesive, both on the upholstery material and on the substrate onto which the material is placed. Due to the growing demands on environmental protection, our company is increasingly working with water-based adhesives only. We have four spray booths, both for small and large parts such as ceiling headliner parts.

DRYING

At DAGRO we use water-based adhesives. The reason? They are much more environmentally friendly. After application, it is then necessary to remove the undesirable moisture carefully, as this is the only way to achieve sufficient adhesion for subsequent upholstering. In order to be able to guarantee first-class quality at all times, we have invested in one automated and two high-capacity static dryers.

DRYING

At DAGRO we use water-based adhesives. The reason? They are much more environmentally friendly. After application, it is then necessary to remove the undesirable moisture carefully, as this is the only way to achieve sufficient adhesion for subsequent upholstering. In order to be able to guarantee first-class quality at all times, we have invested in one automated and two high-capacity static dryers.

RIVETING

Some projects require other ways of joining materials in addition to sewing. One of these is conventional riveting, for which we use pneumatic rivet guns. This process is mainly used for very hard materials and also where very high demands are placed on cohesion, regardless of the aesthetic effect. For conventional riveting we use pneumatic rivet guns.

STAPLING

In the case of some interior parts (especially for orders from the furniture industry), we use a stapling technology for upholstery. The upholstery material is stretched over the part and attached on the opposite side with steel staples.

STAPLING

In the case of some interior parts (especially for orders from the furniture industry), we use a stapling technology for upholstery. The upholstery material is stretched over the part and attached on the opposite side with steel staples.

PLASMA SURFACE TREATMENT

It is a surface treatment of non-polar plastics (PE, PP), where by disturbing the surface tension we increase the adhesive properties of the parts necessary to achieve the required strength in the upholstery process. This process reduces manufacturing costs for processing these types of plastics by eliminating the extra costs of the surface treatment processes such as flame singeing or grinding.

FINAL INSPECTION

In order to achieve maximum satisfaction of our customers, all products undergo a final quality inspection. We place high emphasis on the quality of products shipped to our customers so that they meet all predefined requirements. All products are subsequently registered in our production software and traceable at any time, including all production information. Quality = satisfied customer.

FINAL INSPECTION

In order to achieve maximum satisfaction of our customers, all products undergo a final quality inspection. We place high emphasis on the quality of products shipped to our customers so that they meet all predefined requirements. All products are subsequently registered in our production software and traceable at any time, including all production information. Quality = satisfied customer.